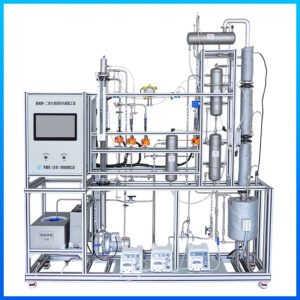

Absorption and Desorption Experiment Device

Through this device, students can learn the structures of packed absorption towers and desorption towers; study the relationship between different spray densities and volumetric mass transfer coefficients under liquid film control.

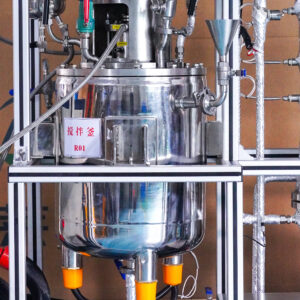

Aspirin Active Pharmaceutical Ingredient (API) Synthesis Practice Device

Aspirin, also known as acetylsalicylic acid, is a long-standing antipyretic and analgesic drug that has been in use for over a century. It has become one of the three classic drugs in the history of medicine and remains the most widely used antipyretic, analgesic, and anti-inflammatory drug worldwide today. Additionally, it serves as a standard preparation for comparing and evaluating other pharmaceuticals. The synthesis process of aspirin active pharmaceutical ingredients (API) involves multiple chemical engineering operation units; therefore, developing a teaching and practical training device for the synthesis and production of aspirin API holds significant practical importance for vocational colleges and higher education institutions.

Bernoulli’s Equation Demonstration Experiment Device

The device consists of a circulation pump, rotameter, acrylic glass pipeline, circulating water tank, and experimental panel. Pressure-measuring glass tubes and inlet/outlet valves are installed on the pipeline. There are 23 pressure measurement points in the pipeline, with two vent points set at the abrupt expansion and contraction sections, and a drain port installed below the pipeline.

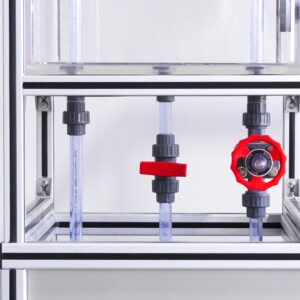

Binary System Vapor – Liquid Equilibrium Data Determination Experiment Device

Through this device, students can understand the significance of determining binary vapor-liquid equilibrium (VLE) data; learn to plot the binary VLE phase diagram; acquire the ability to determine the azeotropic point via the phase diagram of an azeotropic system; and master the method of calculating the activity coefficients of each component using experimentally measured T-P-X-Y data.

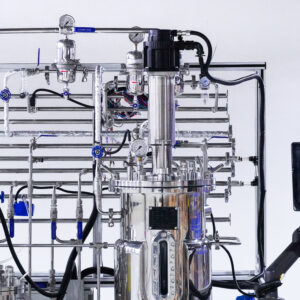

Bio – fermentation Ethanol Production Practice Device

Alcohol is not only an indispensable important solvent and raw material in the chemical industry but also a raw material for blending distilled spirits and other alcoholic beverages. In the medical field, it can be used for disinfection, preservation, sterilization, and the preparation of various medical reagents. In the energy sector, alcohol can also serve as a new fuel alternative to gasoline; compared to gasoline, the greatest advantage of fermented alcohol as a fuel lies in its renewability. Currently, the largest application of alcohol is as fuel ethanol. The bio-fermentation ethanol production process covers multiple chemical engineering operation units; therefore, developing a teaching device for the fermentation-based ethanol production line holds significant practical importance for practical training teaching in vocational colleges and higher education institutions.