SKU:

LPK-IBFE

Category: Typical engineering practice device

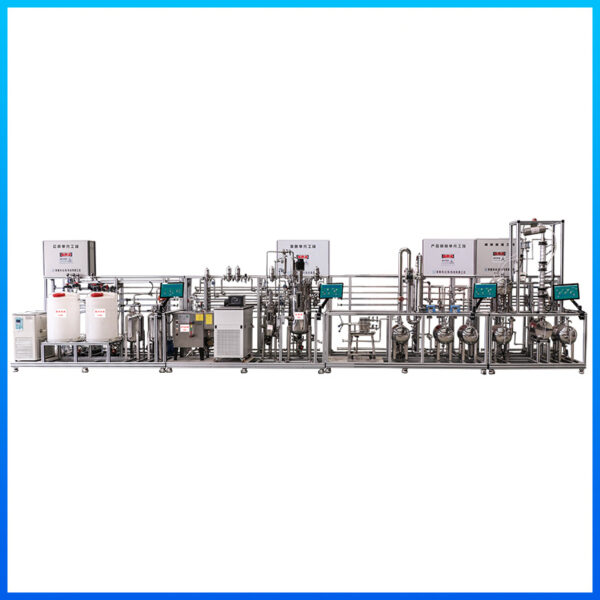

Bio – fermentation Ethanol Production Practice Device

Alcohol is not only an indispensable important solvent and raw material in the chemical industry but also a raw material for blending distilled spirits and other alcoholic beverages. In the medical field, it can be used for disinfection, preservation, sterilization, and the preparation of various medical reagents. In the energy sector, alcohol can also serve as a new fuel alternative to gasoline; compared to gasoline, the greatest advantage of fermented alcohol as a fuel lies in its renewability. Currently, the largest application of alcohol is as fuel ethanol. The bio-fermentation ethanol production process covers multiple chemical engineering operation units; therefore, developing a teaching device for the fermentation-based ethanol production line holds significant practical importance for practical training teaching in vocational colleges and higher education institutions.

Public Unit

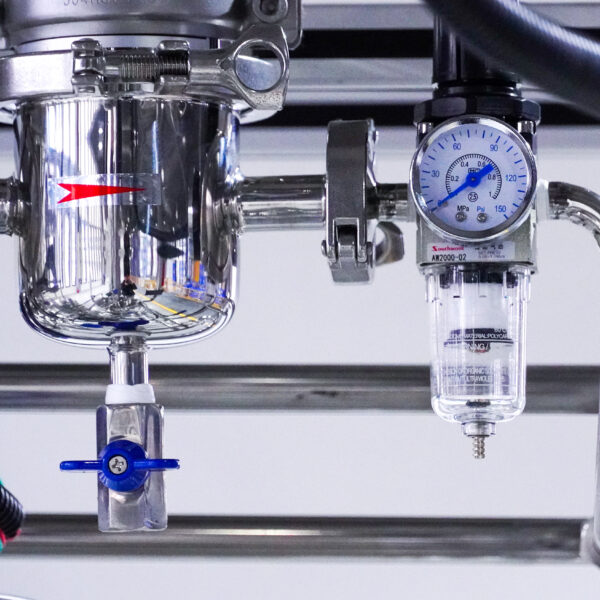

- Provides stable softened water, cooling water, compressed air, and vacuum.

- Adopts on-site touchscreen operation to achieve automatic main control, combined with partial manual operations to enhance hands-on skills.

- Equipment appearance and dimensions: Constructed with a high-quality aluminum alloy frame and casters, with overall dimensions no larger than 2200mm×1120mm×2050mm (length×width×height).

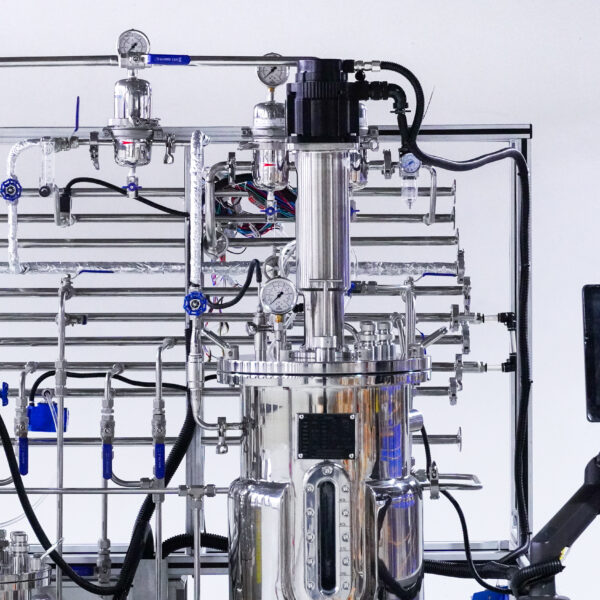

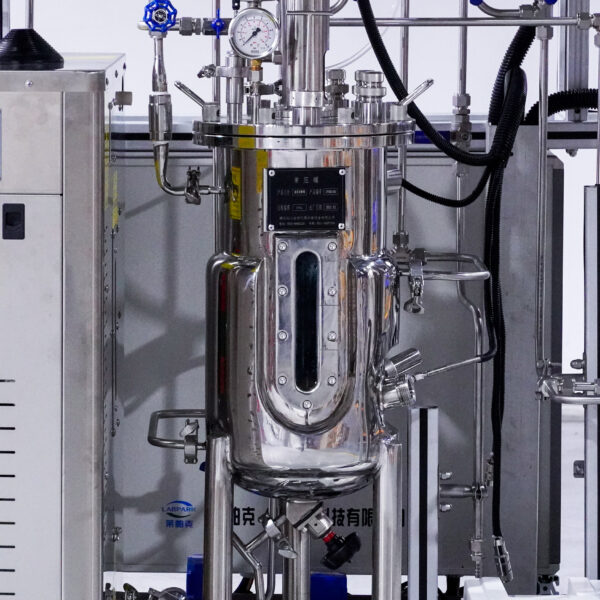

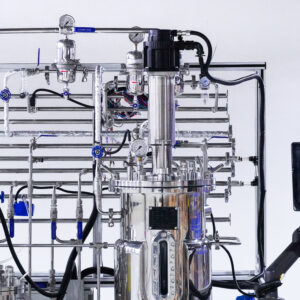

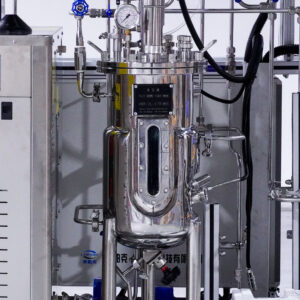

Fermentation Unit

- Equipped with a quantitative feeding function.

- Supports reaction systems such as aerobic fermentation, anaerobic fermentation, and seed culture.

- Features steam sterilization, jacket heat exchange, and air transfer functions.

- The constant temperature water bath enables automatic temperature control to meet the reaction temperature requirements of the fermenter.

- Equipment appearance and dimensions: Constructed with a high-quality aluminum alloy frame and casters, with overall dimensions no larger than 2200mm×1120mm×2050mm (length×width×height).

Product Refining Unit

- Equipped with a quantitative feeding function.

- Supports plate-and-frame filtration operations for solid-liquid separation.

- Supports membrane separation operations to filter glucose macromolecules.

- Equipment appearance and dimensions: Constructed with a high-quality aluminum alloy frame and casters, with overall dimensions no larger than 2200mm×1120mm×2050mm (length×width×height).

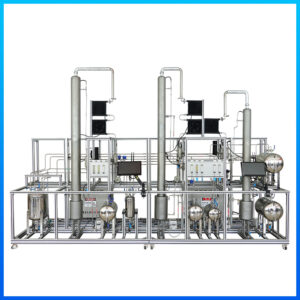

Packed Distillation Unit

- Supports batch distillation and continuous distillation, with adjustable reflux ratio operations.

- The reboiler can be controlled via constant power or pressure self-control to meet the diverse needs of distillation for different materials.

- Requires centralized exhaust of distillation tail gas during the process, with no escape during intermediate stages.

- Equipment appearance and dimensions: Constructed with a high-quality aluminum alloy frame and casters, with overall dimensions no larger than 2200mm×1120mm×2285mm (length×width×height).

Product Inquire Now

"*" indicates required fields