SKU:

LPK-IKDD

Category: Typical engineering practice device

Ethyl Acetate Synthesis Practice Device

Ethyl acetate is a fine chemical product with extensive applications. It exhibits excellent solubility and quick-drying properties, making it a versatile material. As a crucial organic chemical raw material and an outstanding industrial solvent, it is widely used in the production processes of cellulose acetate, ethyl cellulose, chlorinated rubber, vinyl resin, cellulose acetate resin, synthetic rubber, coatings, paints, and other products. The synthesis process of ethyl acetate involves multiple chemical engineering operation units; therefore, developing a teaching device for an ethyl acetate production line holds significant practical importance for practical training teaching in vocational colleges and higher education institutions.

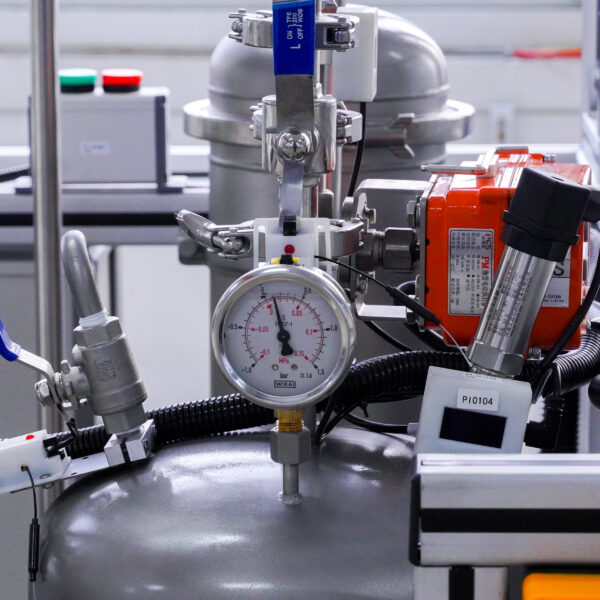

Public Unit

- Provides stable softened water, cooling water, compressed air, and vacuum.

- Adopts central control terminal operation to achieve automatic main control, combined with partial manual operations to enhance hands-on skills.

- Capable of continuous operation and unattended running.

- Equipment appearance and dimensions: Constructed with a high-quality aluminum alloy frame and casters, with overall dimensions no larger than 2200mm×1120mm×2310mm (length×width×height).

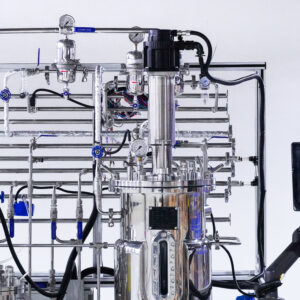

Esterification Reaction Unit

- Equipped with a quantitative feeding function.

- Supports in-line esterification reaction operations.

- Features condensation reflux, filtration separation, and vacuum transfer functions.

- Adopts central control terminal operation for automatic main control, combined with partial manual operations to enhance hands-on skills.

- Equipment appearance and dimensions: Constructed with a high-quality aluminum alloy frame and casters, with overall dimensions no larger than 2200mm×1120mm×3600mm (length×width×height).

Neutralization Unit

- Equipped with a quantitative feeding function.

- Supports liquid-liquid extraction and two-phase separation operations.

- The constant temperature system enables automatic temperature control to meet the reaction temperature requirements of the extraction kettle.

- Adopts central control terminal operation for automatic main control, combined with partial manual operations to enhance hands-on skills.

- Equipment appearance and dimensions: Constructed with a high-quality aluminum alloy frame and casters, with overall dimensions no larger than 2200mm×1120mm×2300mm (length×width×height).

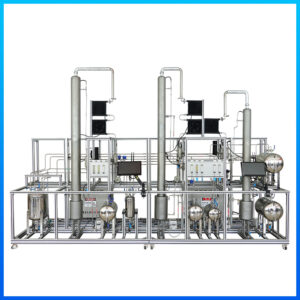

Sieve Plate Distillation Unit

- Supports batch distillation and continuous distillation, with adjustable reflux ratio operations.

- Enables refining, purification, and material recovery operations for ethyl acetate.

- Adopts central control terminal operation for automatic main control, combined with partial manual operations to enhance hands-on skills.

- Equipment appearance and dimensions: Constructed with a high-quality aluminum alloy frame and casters, with overall dimensions no larger than 2200mm×1120mm×2900mm (length×width×height).

Product Inquire Now

"*" indicates required fields