Low – Concentration Carbon Dioxide Capture Experiment Platform

Through this device, students can learn the principle of pressure swing adsorption (PSA) separation, understand the process flow of PSA separation for gas mixtures, comprehend the basic principles of carbon dioxide PSA and the factors influencing the process, and master the experimental methods for determining the breakthrough curve of the adsorption bed.

Multi – functional Drying Experiment Device

Students can learn the structures of tunnel dryers, fluidized bed dryers, and spray dryers through this device; master the determination methods of drying curves and drying rate curves; understand the significance of the process for determining the drying rate curve; and gain knowledge of measuring the humidity of moist air using wet-bulb and dry-bulb temperatures.

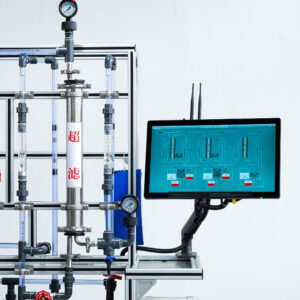

Multi – functional Membrane Separation Experiment Device

Through this device, students can simultaneously learn the working principles and usage methods of three types of filtration membranes: ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO); they can also analyze and calculate parameters such as membrane flux and rejection rate of different membrane modules.

Multi – functional Reaction Experiment Device

Through this device, students can simultaneously understand the structures and process flows of gas-solid catalytic fixed bed reactors, fluidized bed reactors, and stirred-tank reactors; and master the methods of conducting catalyst evaluation experiments using different types of reactors.

Multi – functional Special Distillation Experiment Device

Through this device, students can learn the process flow and operation of continuous distillation; study the principles and processes of azeotropic distillation, and understand the impact of entrainers on the azeotropic point; explore the principles and processes of reactive distillation, and comprehend the influence of the distillation process on the conversion rate of catalytic reactions; examine the principles and processes of extractive distillation, and grasp how extractants affect the relative volatility of components; investigate the process flow of vacuum distillation, and understand the effect of vacuum conditions on distillation operations; analyze the impact of reflux ratio on the separation efficiency of distillation; and master the calculation methods for evaluating the separation efficiency of distillation.

Multi – Kettle Series Mixing Performance Determination Experiment Device

Through this device, students can learn the residence time measurement methods for single reactors and three reactors in series; understand how parameters of the series model characterize the residence time distribution (RTD) and degree of backmixing in continuous stirred-tank reactors (CSTRs); comprehend the physical meaning of model parameter N; and grasp the two ideal flow models: plug flow and perfect mixing.

.png-300x300.jpg)