SKU:

LPK-SSTR

Category: Chemical engineering experimental device

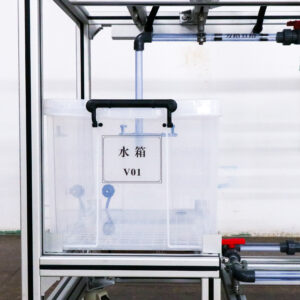

Multi – Kettle Series Mixing Performance Determination Experiment Device

Through this device, students can learn the residence time measurement methods for single reactors and three reactors in series; understand how parameters of the series model characterize the residence time distribution (RTD) and degree of backmixing in continuous stirred-tank reactors (CSTRs); comprehend the physical meaning of model parameter N; and grasp the two ideal flow models: plug flow and perfect mixing.

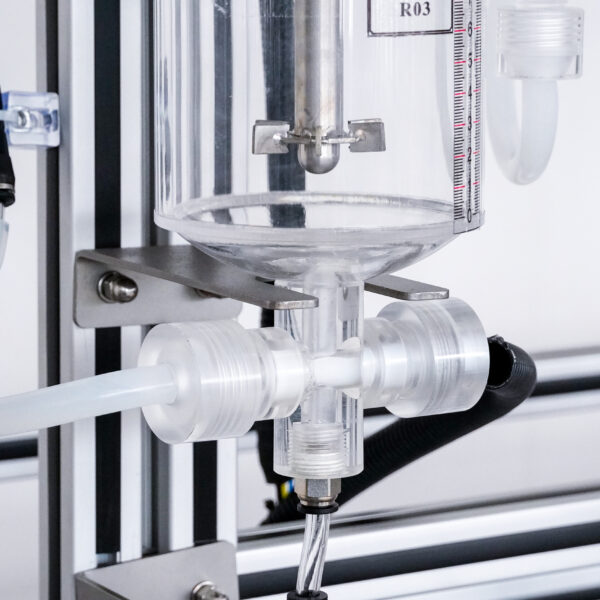

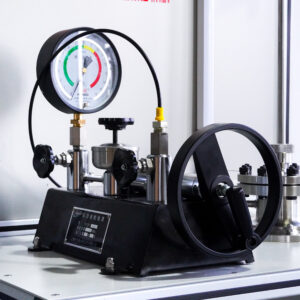

♥ 1. The device uses the pulse tracer method to measure the residence time distribution (RTD). The conductivity meter can accurately detect the tracer concentration at the outlet of each reactor in real time, and the residence time distribution curve is obtained through computer software processing.

♥ 2. The device features professionalism, enabling analysis and study of the residence time distribution of continuous stirred-tank reactors (CSTRs) and the degree of backmixing using parameters from the multi-reactor series model. The model parameter N represents the degree of backmixing in the reactor; the larger N is, the lower the degree of backmixing, thereby guiding students to understand the two ideal flow models: plug flow and perfect mixing.

♥ 3. Equipment appearance and dimensions: The device is constructed with a high-quality aluminum alloy frame and casters, with overall dimensions no larger than 2200mm×580mm×1780mm (length×width×height).

Product Inquire Now

"*" indicates required fields