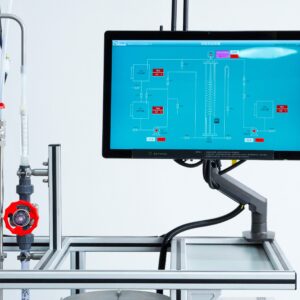

Extraction Experiment Device

Students can familiarize themselves with the structure, process flow, and working principle of the rotary disc extraction tower through this device, and master the method for measuring the height of the mass transfer unit.

General – Purpose Cosmetics Production Practice Device

Fine chemical engineering is a highly comprehensive technology-intensive industry. During production, it involves long process flows, multiple unit reactions, complex raw materials, and strict requirements for intermediate process control. Moreover, it applies to and involves theoretical knowledge and professional skills across multiple fields and disciplines. As one of the most dynamic fields in today’s chemical industry, fine chemical engineering is characterized by diverse product types, high added value, a wide range of applications, and strong industrial relevance. Therefore, mastering the process operations of fine chemical engineering constitutes an important component of teaching.

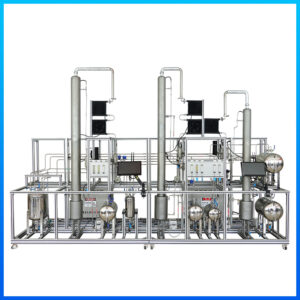

Green Anhydrous Ethanol Refining Practice Device

Absolute ethanol is an important basic organic chemical raw material. The ethylene glycol-based extractive distillation method for producing absolute ethanol overcomes the shortcomings of many traditional processes and enables the preparation of absolute ethanol in arbitrary proportions and scales. The green absolute ethanol refining practice device uses crude ethanol (approximately 40% concentration) as raw material and employs the ethylene glycol extractive distillation method to produce absolute ethanol. The device is equipped with a crude ethanol refining tower, an extractive distillation tower, and an ethylene glycol solvent recovery tower. During the experimental process, the three towers operate simultaneously to achieve repeated use of the solvent. Additionally, the equipment piping follows an industrial actual production piping scheme, which prevents unqualified products from flowing into subsequent sections. Once the equipment stabilizes, continuous cyclic use of the experimental raw materials and extractant can be achieved.

Heterogeneous Separation Demonstration Experiment Device

Through this device, students can understand the structures of gas-solid systems in gravity settling chambers, inertial settling chambers, cyclone separators, and bag filters; while learning about the separation characteristics of gas-solid systems in these devices; and analyzing the energy consumption characteristics of cyclone separators.

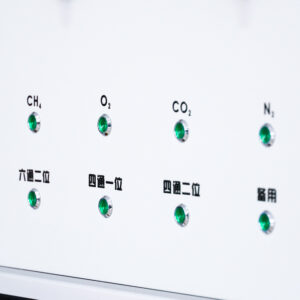

Hydrogen Production and Storage Device by Water Electrolysis

This device primarily comprises a dosage system, electrolytic cell, power supply, electrolyte circulation system, and hydrogen storage system. It is a process that utilizes electrical energy to decompose water into hydrogen and oxygen, with the produced gas being pressurized and stored. It supports quantitative feeding of electrolytes in different proportions, quantitative replenishment of raw materials, and adopts an integrated design concept overall to achieve interlocked control of hydrogen production and storage.

Internal Circulation Gradient – Free Reaction Experiment Device

Through this device, students can understand the structure and process flow of the gradientless reaction experimental device; learn the operations for catalyst evaluation in gas-solid catalytic reaction experiments; and acquire the ability to analyze the conversion rate, selectivity, and yield of catalytic reactions based on experimental data.

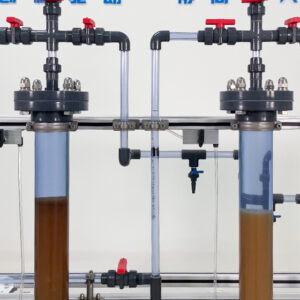

Ion Exchange Experiment Device

Through this device, students can learn the characteristics and process flow of water production by the ion exchange method; they can also learn the working principle and application of ion exchange resins.

.png-300x300.jpg)