Absorption and Desorption Experiment Device

Through this device, students can learn the structures of packed absorption towers and desorption towers; study the relationship between different spray densities and volumetric mass transfer coefficients under liquid film control.

Bernoulli’s Equation Demonstration Experiment Device

The device consists of a circulation pump, rotameter, acrylic glass pipeline, circulating water tank, and experimental panel. Pressure-measuring glass tubes and inlet/outlet valves are installed on the pipeline. There are 23 pressure measurement points in the pipeline, with two vent points set at the abrupt expansion and contraction sections, and a drain port installed below the pipeline.

Circulating Wind – Tunnel Drying Experiment Device

Through this device, students can understand the factors affecting the drying rate curve; by using wet-bulb and dry-bulb temperatures to measure the humidity of moist air, they can master the determination methods of drying curves and drying rate curves, and comprehend the significance of the process for determining the drying rate curve; additionally, they can learn the determination method of the convective heat transfer coefficient between the material and air during the constant-rate drying stage.

Cold Model Tower Demonstration Experiment Device

The device includes the structures and working principles of four different types of trays: sieve trays, bubble caps, serrated trays, and valve trays. The experimental process covers the measurement of single-tray pressure drop, as well as the observation of phenomena such as liquid leakage, mist entrainment, and downcomer flooding.

Comprehensive Extraction Experiment Device

Through this device, students can familiarize themselves with the structure, process flow, and structural functions of each component of rotary extraction towers and vibratory extraction towers; understand the proper operation of extraction towers; determine the influence of rotational speed on separation and purification efficiency in rotary extraction towers and calculate the height of a mass transfer unit (HTU); as well as determine the influence of vibration frequency on separation and purification efficiency in vibratory extraction towers and calculate the HTU.

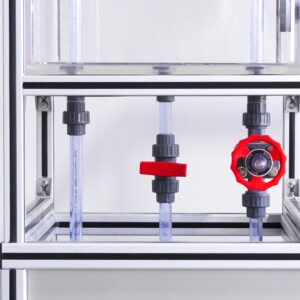

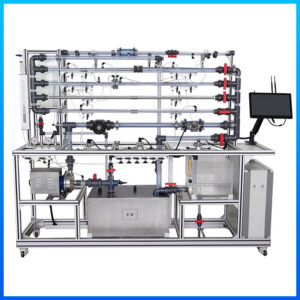

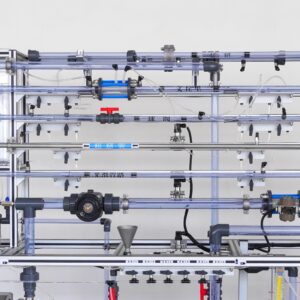

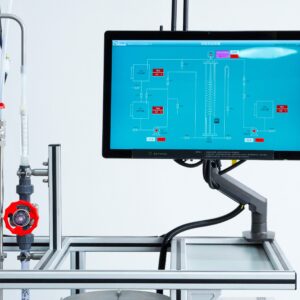

Comprehensive Fluid Mechanics Experiment Device

Through this comprehensive device, students can learn no less than 13 teaching knowledge points, including relatively thin pipes, relatively thick pipes, rough thin pipes, rough thick pipes, laminar flow pipes, local valves, abrupt contraction pipes, orifice plate flowmeters, venturi flowmeters, centrifugal pump performance curves, pipeline performance curves, inverted U-tube manometers, and volume method flowmeters.

Comprehensive Heat Transfer Experiment Device

Master the determination method of the convective heat transfer coefficient αi, and deepen the understanding of its theoretical basis and influencing factors; Master the application of linear regression analysis to determine the values of constants A and m in the heat transfer correlation Nu=AR^mPr^0.4; Deepen the understanding of the basic theory of enhanced heat transfer through data comparison between threaded tubes and smooth tubes; Understand the structure of shell-and-tube heat exchangers and learn the determination methods for their heat transfer coefficients and average driving forces;

Constant – Pressure Filtration Experiment Device

Students can familiarize themselves with the structure and installation sequence of the plate and frame filter press through this device; learn the filtration constant and specific resistance under constant pressure; and learn the relationship between filtration pressure and specific resistance.

Extraction Experiment Device

Students can familiarize themselves with the structure, process flow, and working principle of the rotary disc extraction tower through this device, and master the method for measuring the height of the mass transfer unit.

Heterogeneous Separation Demonstration Experiment Device

Through this device, students can understand the structures of gas-solid systems in gravity settling chambers, inertial settling chambers, cyclone separators, and bag filters; while learning about the separation characteristics of gas-solid systems in these devices; and analyzing the energy consumption characteristics of cyclone separators.

Multi – functional Drying Experiment Device

Students can learn the structures of tunnel dryers, fluidized bed dryers, and spray dryers through this device; master the determination methods of drying curves and drying rate curves; understand the significance of the process for determining the drying rate curve; and gain knowledge of measuring the humidity of moist air using wet-bulb and dry-bulb temperatures.

Reynolds Number Demonstration Experiment Device

Through this device, students can understand the relationship between the flow patterns of fluids in circular pipes and the Reynolds number Re; observe the flow patterns of steady laminar and turbulent flows in circular pipes, and master the criteria for determining flow regimes in circular pipes; learn the method of applying dimensionless parameters for experimental research, and understand their practical significance.