Binary System Vapor – Liquid Equilibrium Data Determination Experiment Device

Through this device, students can understand the significance of determining binary vapor-liquid equilibrium (VLE) data; learn to plot the binary VLE phase diagram; acquire the ability to determine the azeotropic point via the phase diagram of an azeotropic system; and master the method of calculating the activity coefficients of each component using experimentally measured T-P-X-Y data.

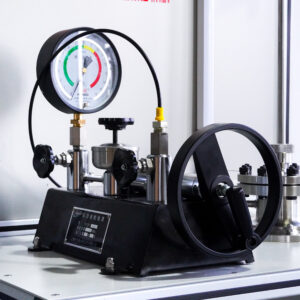

Carbon Dioxide PVT Curve Determination Experiment Device

Through this device, students can understand the critical point, critical pressure, and critical temperature of pure substances; comprehend the thermodynamic states of pure substances, including concepts such as condensation, vaporization, and saturation; learn to plot the CO₂ isotherm on the P-V diagram of pure substances; and acquire the ability to identify the liquid phase region and gas phase region on the P-V diagram of pure substances.

Catalyst Particle Intraparticle Diffusion Effective Factor Determination Experiment Device

Through this device, students can master the measurement of the effective factor η of internal diffusion in catalyst particles and the experimental data of intrinsic reaction kinetics for gas-solid catalytic reactions; they can also acquire the operational processes of catalyst activity evaluation, activation, and regeneration.

Compression Refrigeration Performance Determination Experiment Device

Through this device, students can learn the principles of measuring the compressor refrigeration coefficient and the overall unit refrigeration coefficient, as well as related components; understand the impact of regeneration on the refrigeration coefficient, and learn to properly use the regenerator to improve refrigeration efficiency; master the methods and principles for measuring the calorimeter heat leakage coefficient; and learn to use the R22 pressure-enthalpy diagram to analyze normal operating conditions, saturated operating conditions, and supersaturated operating conditions of refrigeration systems.

Ethylbenzene Dehydrogenation Experimental Device

Through this device, students can master the structure and process flow of gas-solid catalytic experimental devices; they can also master the determination and evaluation of the activity of iron oxide-based catalysts, and regenerate deactivated catalysts by activating with steam to remove coke.

Experimental Device for Determination of Residence Time Distribution and Reactor Flow Characteristics

Through this device, students can learn the methods of measuring residence time in continuous stirred-tank reactors (CSTRs) and tubular reactors; understand how the parameters of the series model characterize the residence time distribution (RTD) of the CSTR and the degree of backmixing, as well as the physical meaning of model parameter N; and comprehend the two ideal flow patterns: plug flow and perfect mixing.

Internal Circulation Gradient – Free Reaction Experiment Device

Through this device, students can understand the structure and process flow of the gradientless reaction experimental device; learn the operations for catalyst evaluation in gas-solid catalytic reaction experiments; and acquire the ability to analyze the conversion rate, selectivity, and yield of catalytic reactions based on experimental data.

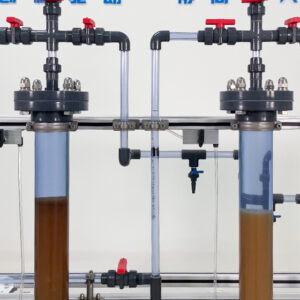

Ion Exchange Experiment Device

Through this device, students can learn the characteristics and process flow of water production by the ion exchange method; they can also learn the working principle and application of ion exchange resins.

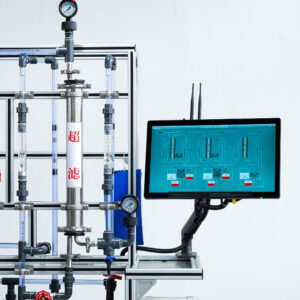

Multi – functional Membrane Separation Experiment Device

Through this device, students can simultaneously learn the working principles and usage methods of three types of filtration membranes: ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO); they can also analyze and calculate parameters such as membrane flux and rejection rate of different membrane modules.

Multi – functional Reaction Experiment Device

Through this device, students can simultaneously understand the structures and process flows of gas-solid catalytic fixed bed reactors, fluidized bed reactors, and stirred-tank reactors; and master the methods of conducting catalyst evaluation experiments using different types of reactors.

Multi – functional Special Distillation Experiment Device

Through this device, students can learn the process flow and operation of continuous distillation; study the principles and processes of azeotropic distillation, and understand the impact of entrainers on the azeotropic point; explore the principles and processes of reactive distillation, and comprehend the influence of the distillation process on the conversion rate of catalytic reactions; examine the principles and processes of extractive distillation, and grasp how extractants affect the relative volatility of components; investigate the process flow of vacuum distillation, and understand the effect of vacuum conditions on distillation operations; analyze the impact of reflux ratio on the separation efficiency of distillation; and master the calculation methods for evaluating the separation efficiency of distillation.

Multi – Kettle Series Mixing Performance Determination Experiment Device

Through this device, students can learn the residence time measurement methods for single reactors and three reactors in series; understand how parameters of the series model characterize the residence time distribution (RTD) and degree of backmixing in continuous stirred-tank reactors (CSTRs); comprehend the physical meaning of model parameter N; and grasp the two ideal flow models: plug flow and perfect mixing.