SKU:

LPK-ISPM

Category: Typical engineering practice device

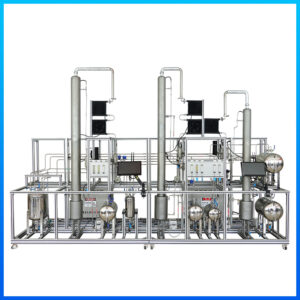

Aspirin Active Pharmaceutical Ingredient (API) Synthesis Practice Device

Aspirin, also known as acetylsalicylic acid, is a long-standing antipyretic and analgesic drug that has been in use for over a century. It has become one of the three classic drugs in the history of medicine and remains the most widely used antipyretic, analgesic, and anti-inflammatory drug worldwide today. Additionally, it serves as a standard preparation for comparing and evaluating other pharmaceuticals. The synthesis process of aspirin active pharmaceutical ingredients (API) involves multiple chemical engineering operation units; therefore, developing a teaching and practical training device for the synthesis and production of aspirin API holds significant practical importance for vocational colleges and higher education institutions.

Public Unit

- Provides stable softened water, cooling water, compressed air, and vacuum.

- Adopts on-site touchscreen operation to achieve automatic main control, combined with partial manual operations to enhance hands-on skills.

- Capable of continuous operation and unattended running.

- Equipment appearance and dimensions: Constructed with a high-quality aluminum alloy frame and casters, with overall dimensions no larger than 2200mm×1120mm×2050mm (length×width×height).

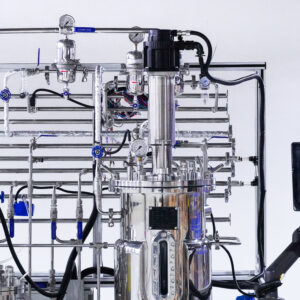

Reaction Unit

- Equipped with a quantitative feeding function.

- Supports experimental operations for the acylation reaction system and neutralization operations.

- Features condensation reflux, filtration separation, and vacuum transfer functions.

- The reaction kettle and neutralization kettle are transparent and visible, facilitating observation of experimental phenomena.

- Adopts on-site touchscreen operation for automatic main control, combined with partial manual operations to enhance hands-on skills.

- Equipment appearance and dimensions: Constructed with a high-quality aluminum alloy frame and casters, with overall dimensions no larger than 2200mm×1120mm×2800mm (length×width×height).

Recrystallization Unit

- Equipped with a quantitative feeding function.

- Enables product purification operations.

- Features condensation reflux, filtration separation, and vacuum transfer functions.

- Equipment appearance and dimensions: Constructed with a high-quality aluminum alloy frame and casters, with overall dimensions no larger than 2200mm×1120mm×2200mm (length×width×height).

Packed Distillation Unit

- Supports batch distillation and continuous distillation, with adjustable reflux ratio operations.

- The reboiler can be controlled via constant power or pressure self-control to meet diverse distillation needs for different materials.

- Requires centralized exhaust of distillation tail gas during the process, with no escape during intermediate stages.

- Equipment appearance and dimensions: Constructed with a high-quality aluminum alloy frame and casters, with overall dimensions no larger than 2200mm×1120mm×2285mm (length×width×height).

Product Inquire Now

"*" indicates required fields