SKU:

LPK-ISOP

Category: Scientific research customized series devices

Experimental Device for Pyrolysis of Solid Waste

Experimental Functions:

- Achieves pyrolysis treatment of solid waste to extract pyrolysis oil.

- Pyrolysis Oil Processing: Purifies pyrolysis oil through distillation, hydrogenation desulfurization, denitrification, and other processes to improve oil quality.

Material and Process:

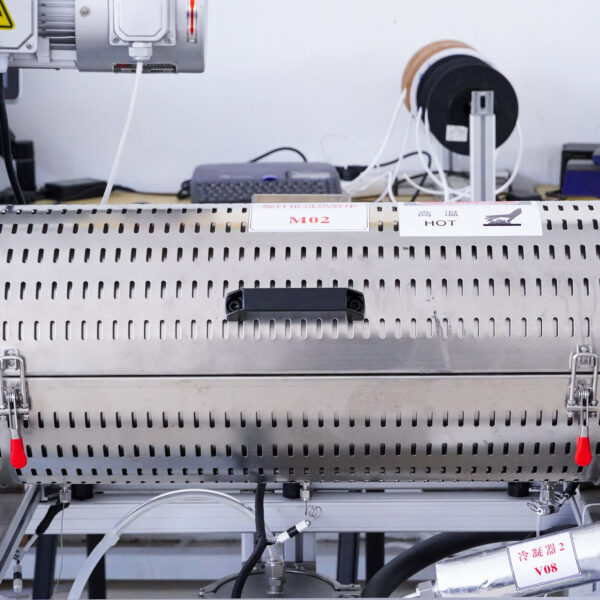

Key components such as the pyrolysis bed, heating furnace, and feed tank are made of 304/316 stainless steel, offering corrosion resistance and high-temperature durability.

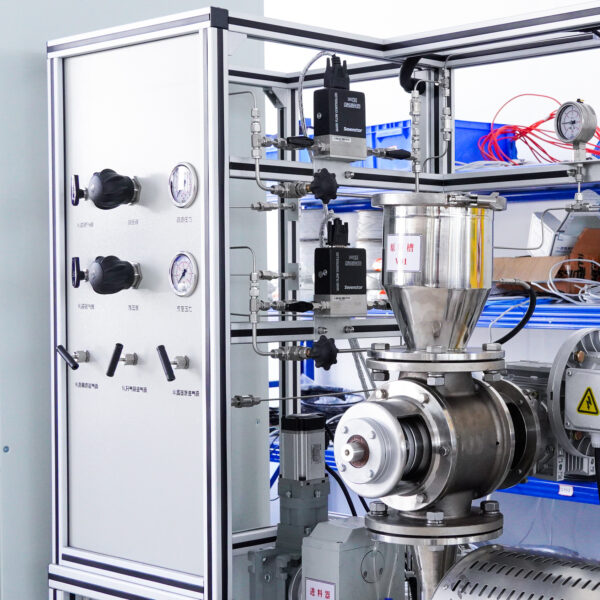

- Special Processes: Utilizes a ceramic fiber electric heating furnace to enhance heating efficiency and temperature uniformity; glass gas-liquid separators and glass column bodies enable easy observation of the experimental process.

Core Structure:

- Pyrolysis Unit: Realizes pyrolysis of solid waste and separates gas-solid and gas-liquid phases.

- Pyrolysis Oil Processing Unit: Performs distillation, hydrogenation desulfurization, and denitrification on pyrolysis oil.

Safety Protection:

- High-Temperature Protection: The heating furnace and key components are equipped with temperature control systems to prevent overheating.

- Pressure Monitoring: Pressure gauges and transmitters are installed to monitor experimental pressure in real time, ensuring safety.

- Explosion-Proof Design: Explosion-proof motors and equipment are used to enhance experimental safety.

Intelligent Configuration:

A 15.6-inch touchscreen integrated with 5G/Bluetooth enables real-time data monitoring and cloud storage.

Application Scenarios:

Teaching experiments; scientific research and development; laboratory research.

Product Inquire Now

"*" indicates required fields