SKU:

LPK-BDIS-C

Category: Chemical Engineering Principle Experimental Device

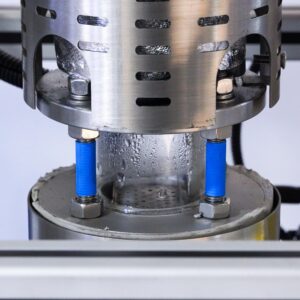

Sieve – Plate Distillation Experiment Device

Through this device, students can learn the structure of a single overflow downcomer sieve tray tower and understand the internal operating conditions of the tower; study the influence of reflux ratio on continuous distillation; comprehend the impact of different feed positions on the distillation process; and gain knowledge of the industrial layout of the equipment to strengthen the concept of engineering.

♥ 1. The device features innovativeness: it is a sieve tray single overflow downcomer tower with observation sight glasses locally installed on the tower body, allowing observation of the internal structure of the tower and the gas-liquid exchange state;

♥ 2. The device enables automatic control of the reflux ratio, supporting selection between total reflux and partial reflux for continuous operation as needed;

♥ 3. At least three different feed positions are reserved on the tower body;

♥ 4. Animation is used to present a 3D stereoscopic view of the device from multiple angles, including simulated displays of gas-liquid mass transfer phenomena on the trays, recognition of the device’s 3D dynamic model, explanations of the engineering layout concept, introductions to the device’s unique features, and guidance on experimental operation procedures;

♥ 5. Equipment appearance and dimensions: The device is required to adopt a high-quality aluminum alloy frame with casters, with dimensions no larger than 2200mm×580mm×2500mm (length×width×height).

Product Inquire Now

"*" indicates required fields